Electrical Discharge Machining: Maximum Precision in Metalworking

Trust our experience for tailor-made solutions that combine innovation and quality.

Electrical discharge machining (EDM) is an advanced technology that allows us to machine metals of any hardness, including those subjected to heat or chemical treatments, guaranteeing extremely precise results.

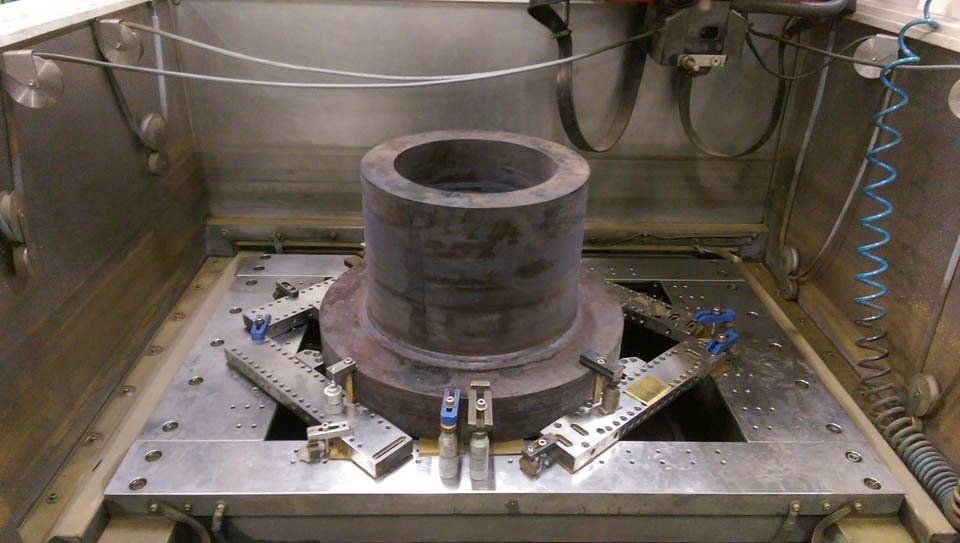

Thanks to our cutting-edge machinery, we create complex geometric and volumetric figures, obtaining details impossible to reproduce with other technologies, such as sharp edges, thin ribs and deep cavities.

This non-contact machining preserves the integrity of the material, making it ideal for high-precision components intended for demanding industries such as aeronautics, automotive, and precision mechanical engineering.

Precision and Surprising Quality with Our Advanced Manufacturing

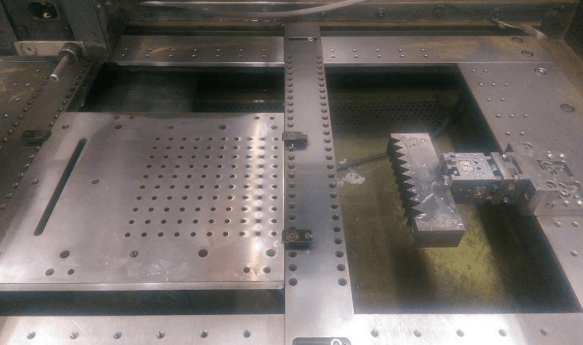

For our EDM processes we rely on high-performance machinery, including Charmille Robofil 640 CC High-Speed And Charmille Robofil 240 CC, capable of working pieces up to 1400x1000x550 mm And 1000x550x220 mm, ensuring maximum precision and quality.

Additionally, we use a

micro-drilling machine capable of making holes with a diameter between

0.2 and 3 mm, ideal for high precision machining on pieces up to

650x350x200 mmThanks to these technologies, we can meet the most complex needs with impeccable results.

request a

preventive

Our team specializes in the creation of special parts machined from solid metal using milling, ensuring precision and quality in every detail.

Thanks to our expertise and advanced technologies, we transform your project into a custom component, perfect for your needs.

From design to construction, we follow every step with the utmost care to offer you reliable and precise results.

Contact us to bring your idea to life!